Improving Productivity & Availability: Nu-Iron’s Experience With Midrex RPS

INTRODUCTION

In September 2004, Nucor acquired the physical assets of American Iron Reduction (AIR), a 1.2 million ton per year cold DRI (CDRI) plant utilizing MIDREX® Direct Reduction Technology. Nucor relocated the plant to Point Lisas, Trinidad and Tobago, in 2005, and increased the capacity to 1.6 million metric tons per year. The new plant, Nu-Iron Unlimited, commenced DRI production on December 30, 2006. The company is the largest shipper of CDRI in the world and has produced more than 19 million tons of cold DRI since start-up, which have been successfully shipped to and melted in Nucor mills in the USA.

Nu-Iron established a Direct Reduction Engineering and Technology (DRET) Team in 2011 to address productivity and availability issues. Its primary focus was to keep the plant running at optimum performance, improve product quality, and minimize downtime. In 2017, The efforts of the DRET produced a 10% increase in annual production and an 11.5% improvement in operating hours (both in comparison to 2016). To further build on the success of the DRET team, Nu-Iron entered into a long-term agreement with Midrex for Remote Professional Services (RPS). This would be a collaboration to find ways to enhance or improve operations by combining the operational expertise of Nu-Iron with the multi-disciplined Midrex team and supporting proprietary software.

BACKGROUND

Following acquisition of the idled AIR plant, Nucor signed a contract with Midrex Technologies, Inc. in April 2005 for upgrading the plant’s capacity to 1.6 million tons per year (t/y) by adding reforming capability and gas compressor capacity. The first cargo of DRI was shipped to Mobile, Alabama, on January 21, 2007.

With no on-site steelmaking capability, Nu-Iron ships all DRI it produces to four ports in the USA: Charleston, South Carolina; Mobile, Alabama; New Orleans, Louisiana, and Morehead City, North Carolina. The product is further transported via barges to Nucor steel mills in Berkeley County, South Carolina; Tuscaloosa, Alabama; Decatur, Alabama; Memphis, Tennessee; Hickman, Arkansas, and Hertford County, North Carolina.

The Nu-Iron plant is shown in Figure 1, with the shaft furnace in the center of the photo, the DRI storage bins behind it to the left, and the receiving and the shipping docks in the background.

FIGURE 1.

Nu-Iron Unlimited, Pt. Lisas, Trinidad and Tobago

CREATION OF THE DRET TEAM

With the latest and most productive DRI technology in use at the Point Lisas site, Nu-Iron sought to push the DRI technology and plant performance even further. To see where they could go, Nu-Iron began benchmarking their operations and comparing themselves to other MIDREX Plants. They determined that there was room for improvement.

The company had goals of setting new standards and breaking internal and external records. With a clear vision set, next came creation of a team empowered to make changes. In 2011, Nu-Iron established a Direct Reduction Engineering Technology (DRET) Team, with an initial focus of planning and process analysis. Professionals from the plant’s mechanical and electrical engineering staffs were added in 2014, and the Team was further expanded from 2014-2017 to include members drawn from process engineering, a refractory specialist, a control systems engineer, senior technicians and specialists, and a mechanical engineer from Midrex, who functioned as an onsite liaison.

The DRET Team takes a broad view of various aspects of plant operation in order to define realistic and achievable goals. Once defined, strategies are systematically outlined and implementation procedures are established to attack the challenges. The Team’s responsibilities include major shutdown planning, creating and maintaining a 5-year “living document” for plant maintenance and operations, conducting root cause analysis investigations, developing equipment preventive maintenance procedures, and implementing the Management of Change process.

With the leadership of the DRET Team, Nu-Iron embarked on ways to improve operation through minimizing unscheduled downtime. Thermography and vibration analysis technologies were adopted to enhance the preventive maintenance programs. Thermography and oil and vibration analysis are used to effectively monitor the health of vital equipment, to reduce wear, predict maintenance needs, and limit the number of unscheduled plant stops.

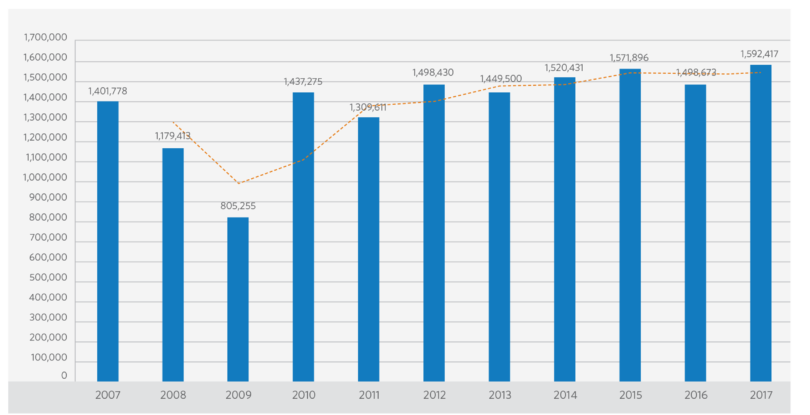

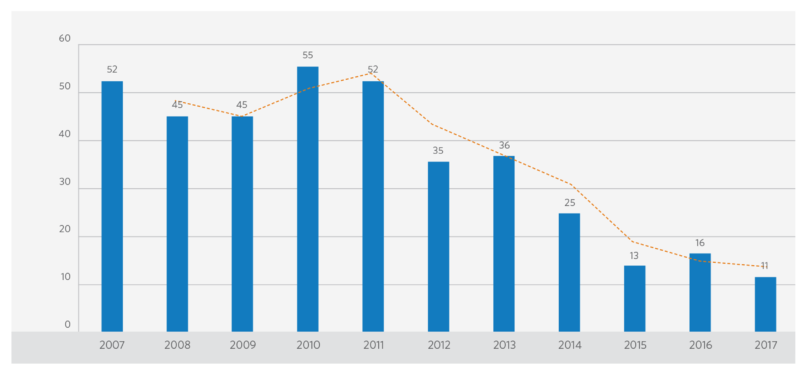

The effectiveness of the DRET Team was obvious in the results achieved in 2017. Annual production was increased by 10% to almost 1.6 million tons (Figure 2) and plant annual operating hours were increased by 11.5% to 7,860 as a result of decreasing plant stops by five-fold (Figure 3).

FIGURE 2.

Annual CDRI Production (2007-2017)

FIGURE 3.

Number of Plant Stops (2007-2017)

NEED FOR CONTINUAL IMPROVEMENT

Although the results achieved in 2017 were in keeping with Nucor’s relentless quest for excellence, it was felt there was room for further improvement. Nu-Iron had achieved great success from the DRET Team’s efforts, but there was a need to continue evolving in order to keep improving.

In 2018, Midrex approached Nu-Iron with a proposal for a suite of services that included the ability for Midrex’s engineering personnel to observe the operation of Nu-Iron’s plant remotely from their RPS control room in Charlotte, NC. Although in the current structure, Midrex and Nu-Iron interact with a ticketing system to identify items to work on, the original RPS proposal included:

- Review of plant start-up and shutdown operations

- Review of plant operations during upset conditions

- Analysis of “pain points” with proposed solutions

- Real time monitoring of plant conditions during start-up from cold conditions

- Investigation of special requests made by Nu-Iron

Two of the “pain points” identified by Nu-Iron and Midrex were possible furnace channeling and material plugging in the proportioning hopper.

FURNACE CHANNELING

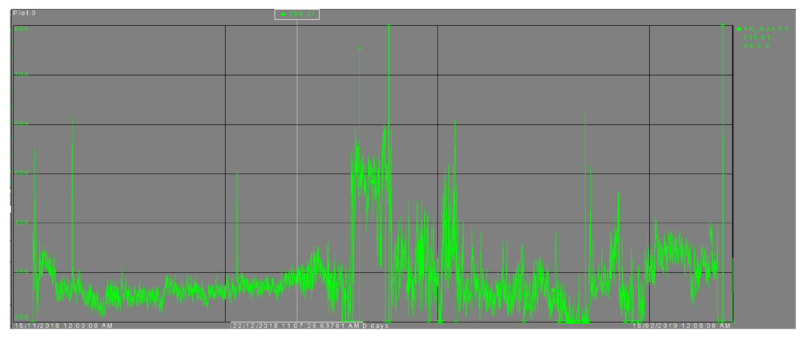

Nu-Iron was aware of erratic bed temperatures from their analysis (Figure 4), which suggested erratic behavior of the bed at higher discharge rates. A higher standard deviation in metallization was noticed (approximately 0.8%), and other parameters showing response to bed temperatures (such as process gas CO2 ) confirmed that some instability in the material flow was occurring.

FIGURE 4.

Nu-Iron Analysis of Bed Temperature Fluctuations

With Nu-Iron focusing on the day to day operation, Midrex RPS was able to focus on identifying all possible causes, or potential operating improvements.

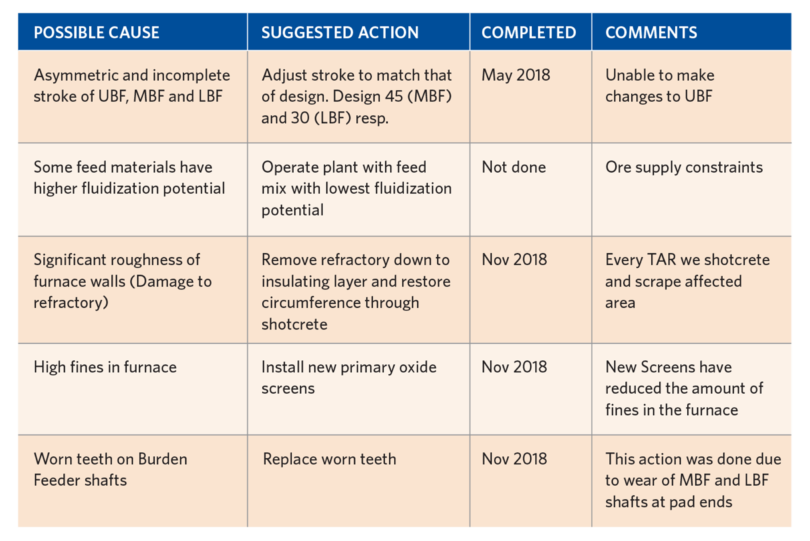

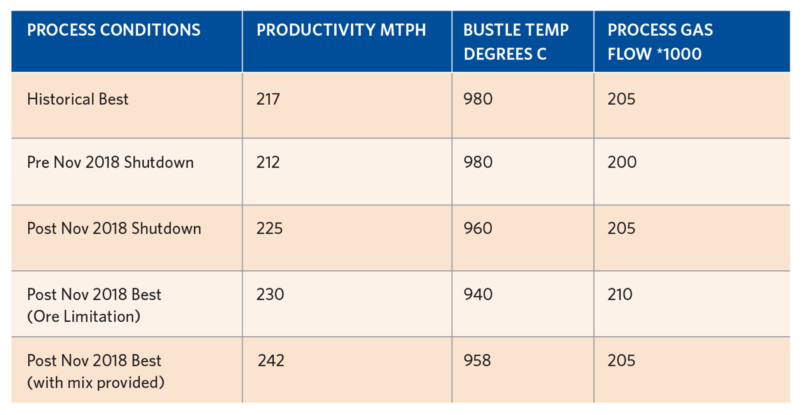

When looking at solutions or trying to identify root causes, the teams frequently developed a cause-and-effect diagram. This required both teams to work in unison, with many of the required verifications or checks done on-site. To develop a cause-and-effect diagram, Nu-Iron and Midrex prepared a list of all possible causes with suggested actions. An example for finding a solution for erratic bed flow is shown in TABLE I.

One of the possible causes involved material fluidizing. Using proprietary software, Midrex used the size distribution data provided by Nu-Iron of their various oxide pellet suppliers to check the material fluidization. This study showed the current feed mix blend to be susceptible to fluidizing. A new blend was suggested to reduce this potential. Once implemented, the results of the efforts from both teams were obvious with the increase in production shown in TABLE II. It should be noted that achieving this increase in production was not a result of any one change or adjustment, but rather a combination of many mutually agreed changes or adjustments by both Nu-Iron and Midrex RPS.

TABLE I.

Possible Causes for Furnace Channeling and Actions Taken

TABLE II.

Results of Actions Taken

PLUGGING IN THE PROPORTIONING HOPPER

In November 2018, Nu-Iron changed the proportioning hopper and furnace feed legs. Alignment of the legs to the hopper was checked visually, and only reversed ledges were present. Vibrators were installed on all the feed legs to function on timer sequence during operation. High fluctuations in top gas temperature were observed 1-2.5 months after starting up following cleaning of the hopper, as shown in Figure 5, indicating possible blockages in the charge hopper. No significant loss of productivity was noticed; however, it could become a reason to stop the plant if left unresolved.

FIGURE 5.

Nu-Iron Analysis of Top Gas Temperature Fluctuations

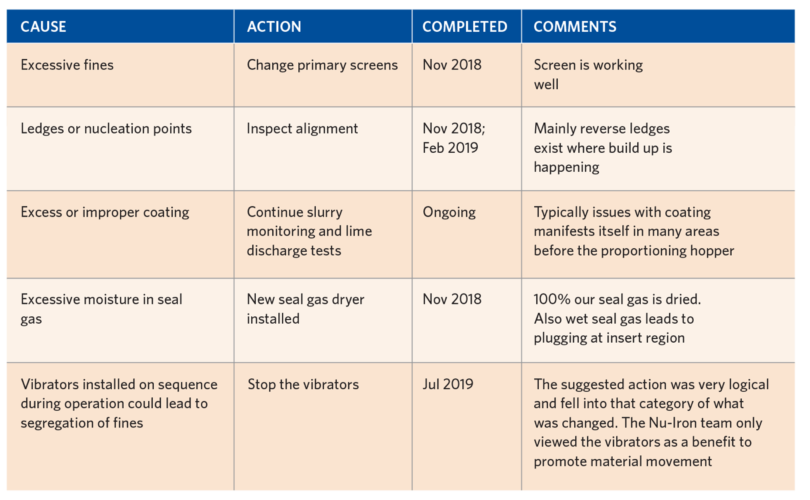

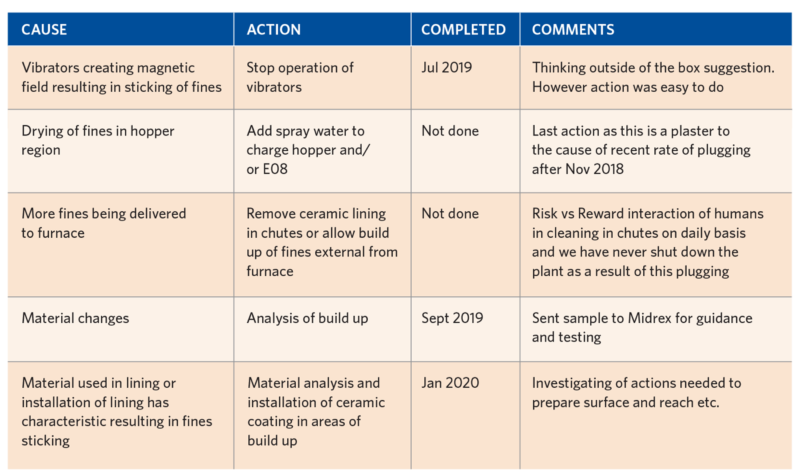

Nu-Iron and Midrex developed an extensive list of possible causes and suggested actions from analysis of the plant data and RPS monitoring (TABLE IIIA and IIIB). Each possible cause was checked and eliminated from the list if it was determined not to be contributing to this effort.

The plant was restarted in November 2018, after a planned maintenance shutdown and operated 1-1.5 months before high fluctuations in top gas temperature were observed. When Nu-Iron brought the plant down in February 2019, the proportioning hopper was cleaned and inspections were conducted. Similar behavior was observed 2-2.5 months after the plant went back into operation. The plant was shut down in June 2019 for scheduled maintenance, at which time the hopper was cleaned and inspected and some areas were polished. Upon restarting plant, Nu-Iron stopped operation of the vibrators.

In early September 2019, the plant was shut down to change a motor. No irregular and/or high swings in the top gas temperature were observed up to this point. The hopper was inspected and build up similar to that before was found, which led to the following conclusions:

- The DRET Team had never considered that the vibrators could possibly aggravate the hopper plugging problem, as they are seen as useful in promoting material flow.

- The input and discussion with the Midrex RPS team has helped identify possible causes.

It must be noted that although this problem has not yet been successfully resolved, it highlights the benefit of both teams “brain storming” in an effort to successfully resolve an issue.

TABLE IIIA.

Possible Causes for Hopper Plugging and Actions Taken

TABLE IIIB.

Possible Causes for Hopper Plugging and Actions Taken

REDUCING OPERATOR ERRORS DURING PLANT START-UPS

One of the consequences of increased availability and less plant downtime was that new DCS operators were not getting practical experience in restarting the plant. In the past, before a new DCS operator would get confirmed in his position, he needed to have three successful plant start-ups; however, it was no longer possible to wait on three plant start-ups to confirm DCS operators. DCS operators were being confirmed based on “explained knowledge” of a plant start-up as opposed to “displayed knowledge”. This resulted in an increase in “operator errors” during plant start-ups.

Nu-Iron and Midrex developed three main ways to address this issue. These three approaches have allowed Nu-Iron to reduce the number of “operator errors” during plant operation and plant start-up and improved the efficiency of the restart to reduce the time to achieve prime production and reduce the amount of remet generated.

1. Review by the Process Engineering Team of plant start-ups and stops due to “operator error”.

The Process Engineering Team reviews every plant start-up and generates a report that includes the following:

- Summary of the plant start-up

- Positive observation during the start-up

- Potential opportunities for improvement

A report is also generated whenever there is a plant stop due to “operator error”. The report identifies the following:

- Actions taken by the operator

- Root cause of the error

- Corrective actions to prevent reoccurrence

These reports are discussed with all DCS operators. The valuable feedback from the process team and the discussion it engenders is used to help improve the start-up actions of the DCS operators, as well as review of Nu-Iron’s start-up procedures. This has recently been further enhanced by having the RPS team also review plant start-ups to provide further insights that may be missed by the Nu-Iron Process Team.

2. Real-time oversight of plant start-up by Midrex RPS team when restarting from a planned outage.

Once Nu-Iron has a plant start-up from a planned outage, Nu-Iron engages the services of the RPS team to observe the plant restart remotely and communicate with the process engineering personnel on site during the start-up. This oversight has provided guidance to the process team in real time and has helped to further improve Nu-Iron’s plant start-ups.

3. Development of an Operator Training Simulator (OTS).

Nu-Iron, Midrex, and a third party signed an agreement in 2017 to develop an Operator Training Simulator to simulate a plant start-up from idle to completion of reforming. The simulator currently focuses on the gas circuit (and not the shaft furnace). This project took over two years to complete to ensure that the simulator mirrored the “feel” of an actual plant start-up. The simulator was delivered to Nu-Iron in late 2019, and Nu-Iron started using it with experienced DCS operators to ensure that they felt it replicated the plant restart experience.

The feedback from the experienced DCS operators has been extremely positive, and Nu-Iron have has started using the simulator with less experienced DCS operators. Nu-Iron is in discussion with Midrex and the 3rd third party to develop further modules to the OTS.

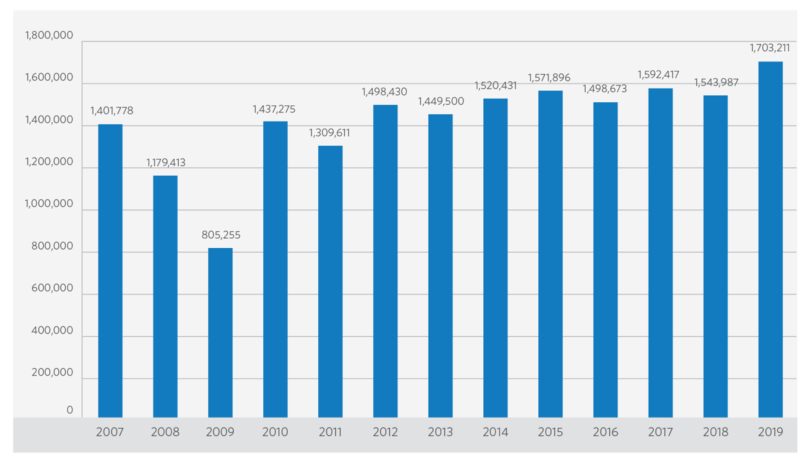

As a result of the cooperative efforts of the Nu-Iron DRET Team and Process Engineering Team and the Midrex RPS Team, production in 2019 reached an all-time high (see Figure 6) and several availability records were set.

FIGURE 6.

Annual CDRI Production (2007-2019)

SUMMARY

The Nucor culture inspires high performance and results-driven operations that stresses safety and teamwork. The DRET Team embodies core Nucor values and the spirit to improve, looking to push technology and performance further while creating a safe and prosperous work environment. Nu-Iron has been able to improve productivity and availability by creating the DRET Team to focus on root causes of plant issues and implementing prompt, effective corrective actions.

In 2018, Nu-Iron engaged the services of the Midrex RPS team in response to the challenge to continually improve. “Pain points” that Nu-Iron’s operations and maintenance personnel were wanting to manage are being eliminated with the integration of Midrex into the Nu-Iron operations team. The collaborative efforts of the Nu-Iron DRET Team and the Midrex RPS team have established new goals and set new standards for direct reduction ironmaking, resulting in the Nu-Iron plant setting numerous production and availability records in 2019 and performing beyond design ratings:

- Producing more than 1.7 million tons of CDRI (Figure 6)

- Averaging 224 t/h in January 2019

- Averaging 96.1% metallization and 2.66% carbon

- Operating in excess of 8,000 hours by maintaining a low number of overall plant stoppages, as well as a low level of stoppages due to operation

“90% of issues can be solved through internal focus, but 100% can only be achieved through external inclusion”

– Ronnie Dabideen

As a key part of Nucor’s ore-based metallics (OBM) strategy, the Nu-Iron plant is one of the world’s most advanced DRI operations. It is based on flexibility, inclusion, and performance. Nu-Iron delivers world class DRI product quality while maintaining a safe and productive work environment. The plant has a DART rating of 0.0 (DART is a safety metric that stands for “days away, restricted or transferred”). Nu-Iron’s DART is well below the national industry average of 1.67.

Typical Nu-Iron DRI has metallization greater than 96% with carbon content of 2.6% or higher. Their product specs exceed the standards of many other operating DRI facilities. In fact, any DRI produced with met lower than 96% is considered “remet” by Nu-Iron. Although “remet” does not have an industry standard definition for metallization percentage, typically anything under 89% is considered “remet”; therefore, Nu-Iron’s “remet” would be considered acceptable product by most DRI plants throughout the world.