Direct Reduction Technology

The MIDREX® Process – The world’s most reliable and productive direct reduction ironmaking technology.

Learn More

The MIDREX® Process – The world’s most reliable and productive direct reduction ironmaking technology.

Learn More

Midrex provides a dependable and clean source of iron to produce high grade steel with low emissions.

Learn More

Midrex Technologies, Inc. recognizes the importance of protecting the environment and conserving natural resources.

Learn MoreAs global efforts intensify to reduce CO2 emissions, MIDREX offers scalable solutions for transitioning towards sustainable ironmaking practices. Dive into this article from Geoff Wallwork, Midrex's Global Solutions Principal Engineer.

Learn MoreCharlotte, North Carolina, USA (March 31, 2024) – K.C. Woody has been named President & CEO of Midrex Technologies, Inc. effective immediately and Stephen Montague, former Midrex CEO will continue…

Midrex has a long-standing tradition of teammates contributing their time and money to benefit those in need in our community, while supporting valuable medical research. This year, the Leukemia &…

Congratulations to Cleveland-Cliffs for being selected!

If awarded, the Company would replace its existing blast furnace at its Middletown Works Facility in Middletown, Ohio with a 2.5mtpa Hydrogen-Ready MIDREX Flex Plant and two 120 MW Electric Melting Furnaces (EMF) to feed molten iron to the existing infrastructure already on site.

The process will dramatically reduce carbon emissions intensity, and will consolidate Middletown Works as the most advanced, lowest GHG emitting integrated iron and steel facility in the world. The facility will have the flexibility to be fueled by natural gas, which would reduce current ironmaking carbon intensity by over 50%; a mix of natural gas and clean Hydrogen; or clean Hydrogen, which would reduce current ironmaking carbon intensity by over 90%.

Read their news releaseWe are committed to providing the best-proven method for decarbonization in the iron and steel industry, direct reduction.

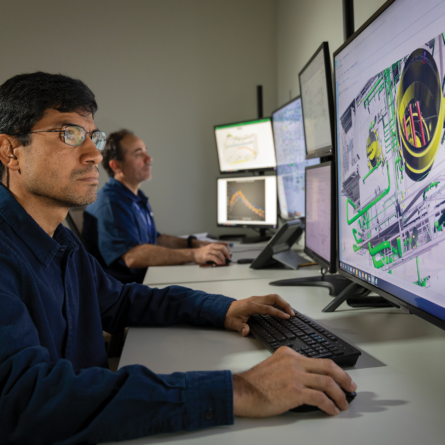

Watch VideoAt Midrex, you will do work that matters, with people who believe you matter. The work won’t be easy. But it will be worth it, as we work together to transform our industry.

Career Opportunities