There’s More to a Midrex Project Than Meets the Eye

Midrex is world renowned for designing, supplying, providing construction advisement, and commissioning direct reduction plants along with making certain that these plants have long and successful operating lives.

Together with our strategic construction partners (Kobe Steel Group, Primetals Technologies, and Paul Wurth), we support our clients from project conceptualization through transition to normal operations. Midrex involvement continues by offering ongoing support through our Technical Services and Global Solutions teams to ensure our clients can maximize the value of their investments.

A MIDREX® Direct Reduction Plant project typically involves seven distinct phases: Project Conceptualization, Planning and Contracting, Design & Development, Construction, Startup & Commissioning, Performance Testing, and finally Handover & Project Closure.

In the first phase, we work with clients to identify the basic project concept, perform a pre-feasibility study, identify and test feed material sources, provide permit level engineering information to assist our clients with obtaining the necessary permits for the facility, as well as explore and provide access to Export Credit Agency (ECA) financing solutions.

During the Planning & Contracting phase, we work hand-in-hand with clients to fully develop a detailed technical specification for the project, an execution plan/specification, and a mutually acceptable contract.

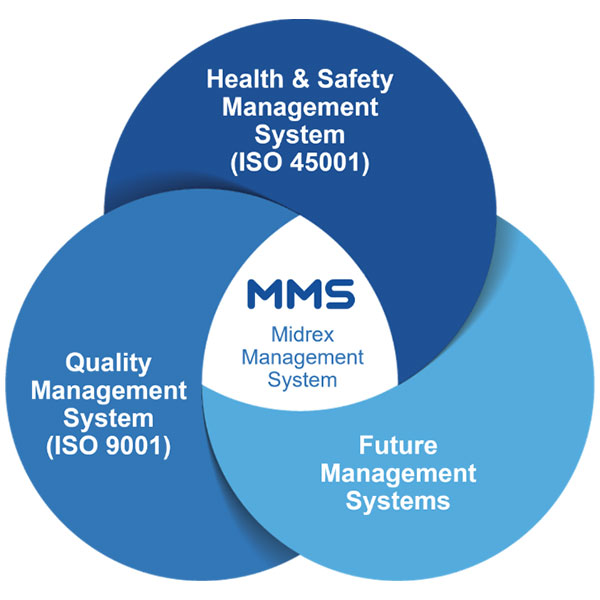

Following contract signing, we move into the Design & Development phase. The first step is to conduct a joint kickoff meeting with the execution teams of all parties to solidify the execution plan and ensure all lines of communication are established. After the kickoff, our teams immediately get to work executing the basic and detailed engineering aspects of the project. Our teams quickly integrate our activities with our strategic partner(s), as well as with client engineering partners / balance of plant (BOP) engineering firms that also participate in the project. As the Development phase continues, our teams commence ordering materials and equipment for the project. Throughout execution, Midrex adheres to its ISO 9001 certified quality program ensuring all design documentation and vendor manufacturing programs meet our strict requirements.

The Construction phase typically starts with our client executing all civil works and underground infrastructure for the DRI plant site. These activities include leveling & grading, piling & foundations, as well as utilities feeds that may be placed underground, such as power, natural gas, hydrogen, water, and sewer necessary for the plant. During this time and under the observation of Midrex advisors, materials and equipment are shipped to site. Our advisors help ensure that materials and equipment are received, stored, and maintained in accordance with manufacturer requirements until the time they are installed.

Midrex and our partners actively collaborate with our client teams to optimize the deployment of our construction advisors based on construction progress. Our initial advisors typically arrive as materials shipments begin and about the same time as the first structural columns are placed for the shaft furnace tower. As the work progresses, we will provide subject matter expert advisors for each discipline including refractory specialists to help guide our client teams through construction process.

Operator training is another critical activity that is performed during this phase. Midrex typically provides supervisor-level and operator-level training for our clients. The supervisor training is classroom-based and the operator training is divided into a classroom phase and an onsite phase at an existing operating plant.

Approximately 3 to 4 months before reaching the end of construction (mechanical completion) for a DRI plant project, Midrex begins to mobilize our start-up & commissioning team to start Pre-Commissioning and Cold Commissioning efforts together with the client’s operations team. During Pre-Commissioning, the teams verify that all items of plant equipment, systems, and services are completed and are ready for commissioning. Cold Commissioning is divided into single equipment cold commissioning, to verify the functionality of the equipment within a system, and system cold commissioning, involving multiple pieces of equipment to verify the functionality of the system. Some examples of the activities that are performed during Cold Commissioning include: powering up equipment, safety interlocks checks, stroking valves, local operation, uncoupled and coupled equipment runs, adjustment of alarms & setpoints. Typically, at the end of Cold Commissioning, the MIDREX Shaft Furnace is filled with iron oxide pellets.

Once each system completes Pre and Cold Commissioning, the Midrex start-up & commissioning team will lead the project into Hot Commissioning, which typically starts with lighting the auxiliary burners, subsequent heat up, a controlled refractory dry-out process, and conducting hot leak checks. Once this is complete, our teams will light the main burners and continue to bring the plant up to process conditions. During this time, our teams will continue to perform process and equipment interlock checks, adjustments, and overall optimization.

After completion of Hot Commissioning, the team will transition to plant start-up. Start-up begins with the addition of process natural gas into the feed gas, which starts the reduction process in the furnace.

Our teams will continue to operate the DRI plant to ensure stabilized operation and to achieve DRI product quality. Once a specified number of tons of quality DRI are produced, our teams will declare “First Product.” This is typically the first critical milestone signifying that the DRI plant is ready for operation and is often the transition point to the next phase.

After reaching “First Product,” we will typically transition directly into the Performance Testing phase of the project. During this phase, the Midrex start-up and commissioning team along with the client operations team will continue to operate the DRI plant in an optimized manner over a specified period of time to achieve or exceed predefined performance metrics for the facility. These metrics typically include production rates, carbon content in the product, metallization, and other consumption factors. Once all parameters have been achieved, our teams will sign off and declare “Plant Acceptance.”

Once “Plant Acceptance” is achieved, the Midrex team will typically transition all operational decisionmaking to the client and begin the process of demobilization from the site. However, should a client have a need for continued support, Midrex Global Solutions can provide onsite operator support, as well as Remote Professional Services (RPS) from our DCS control room in Charlotte, NC. At this stage, the Midrex project team will move into the final phase of the project – Handover & Project Closure.

During this phase, our teams will finalize and issue as-built drawings for the project (where applicable), close out contracts, perform lessons learned reviews, archive project documentation, and provide warranty administration throughout the warranty period for our clients.

Midrex has a storied history of executing complex DRI plant projects throughout the world with our global client base. Midrex engineers and project execution teams are among the best and most experienced in the world when it comes to DRI technology. What sets Midrex apart is our collaborative approach to project development and execution, as well as our guaranteed plant performance backed by the Midrex name.

It takes innovation, initiative, and a passion for excellence to harness the potential of direct reduction technology. And experience, expertise, and commitment to implement projects on-time and on-specification throughout the world backed by a dedicated aftermarket services team. It is how Midrex has delivered the best investment value for more than 50 years and continues to set the example for sustainable ironmaking solutions.

But it is what happens after start-up and commissioning that separates Midrex from other technology suppliers. We enter into a two-way technology licensing agreement with our clients, which brings together the collective expertise of Midrex engineering and technology development and the worldwide operating experience of the family of MIDREX Plants. This exchange of knowledge and practical know-how is what keeps MIDREX Technology fresh, vibrant, and on the leading edge.

In this issue, you can read about the initial success of a pillar of the emerging Algerian steel industry, Tosyali Algerie, and the latest developments in the International Iron Metallics Association (IIMA) project to establish a more accurate schedule for handling and shipping DRI fines. Plus, we celebrate the 40-year anniversary of Midrex becoming a member of the Kobe Steel Group, and MIDREX Plants achieving significant operational milestones in 4Q2023.