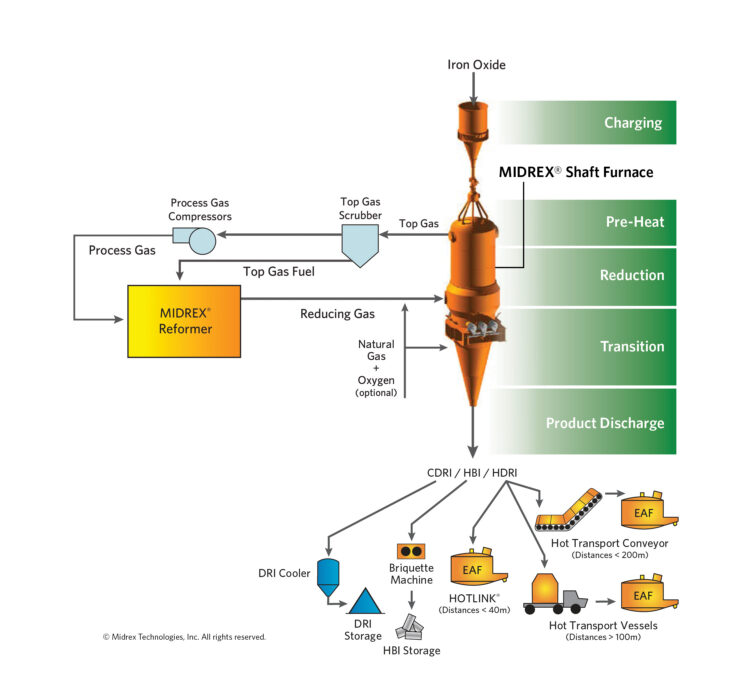

Shaft Furnace

The shaft furnace is where iron ore is converted to metallic. Iron oxide, in pellet or lump form, is introduced through a proportioning hopper at the top of the shaft furnace. As the iron ore descends through the furnace by gravity flow, it is heated, and the oxygen is removed from the iron ore (reduction) by counterflowing gases that have a high H₂ and CO content. These gases react with the iron oxide in the iron ore and convert it to metallic iron, leaving H₂O and CO₂.

MIDREX Plants can be switched from one DRI form to another with no disruption of product flow – CDRI to HBI, CDRI to hot DRI (HDRI), or HDRI to HBI. Product can be produced simultaneously in any combination.

Cold DRI (CDR): DRI that is cooled prior to discharge. This product is mainly used in EAF applications and has a tendency to re-oxidize in wet environments if not properly handled and stored.

Hot Briquetted Iron (HBI): A DRI product hot discharged from the MIDREX® Shaft Furnace into a roller-type press that molds the reduced material into dense pillow-shaped briquettes. This product is used in EAFs, blast furnaces and BOFs.

Hot DRI (HDRI): This product is like CDRI physically yet contains heat from the reduction process to help make EAF operations more efficient and productive.

Hot Transport

In EAF steelmaking, hot transport/hot charging is an effective means of lowering the cost per ton of liquid steel by reducing power and electrode consumption, as well as increasing EAF productivity – making it possible to downsize the electrical system for a greenfield EAF meltshop.

The most efficient route, DRI can be discharged hot and fed to a briquetting machine for production of HBI, or fed hot, as HDRI to an EAF. The MIDREX® Direct Reduction Process fueled by natural gas paired with an electric arc furnace (EAF) has the lowest CO² emissions of any commercially proven steelmaking route using virgin iron ore at 1.1 – 1.2 kg CO² / kg steel.

Reformer

To maximize the efficiency of reforming, offgas from the shaft furnace is recycled and blended with fresh natural gas. This gas is fed to the reformer, a refractory-lined chamber containing alloy tubes filled with catalyst. The gas is heated and reformed as it passes through the tubes. The newly reformed gas, containing 90-92% H₂ and CO (syngas), is then fed hot directly to the shaft furnace as reducing gas. The catalysts within the reformer tubes help speed up the reactions.

Heat Recovery

The thermal efficiency of the reformer is greatly enhanced by the heat recovery system. Sensible heat is recovered from the reformer flue gas to preheat the feed gas mixture, the burner combustion air and the natural gas feed. In addition, depending on the economics, the reformer fuel gas may also be preheated.

The MIDREX® Process is unsurpassed in the Direct Reduction industry in terms of production and process flexibility to meet the constantly evolving nature of steelmakers and ore-based metallics providers. Adjustable product quality and the flexibility to produce various forms of iron together with some of the best production records industry-wide make MIDREX Plants the most profitable DRI plants in the world to own and operate.

Plant Availability

MIDREX® Plants exceed its annual rated capacity on an annual basis. Hours of operation are best indicator of value (Operating Hours x Hourly Capacity = Annual Production = Profits)

Production Reliability

Proven long-term performance and availability producing more than 60% of the world’s DRI since 1984. Built on state-of-the-art technology, fast start ups.

Process Flexibility

Multiple feed, energy sources, reducing gas, and discharge options.

The MIDREX® Shaft Furnace