From the Latest Issue

Mar 21, 2024

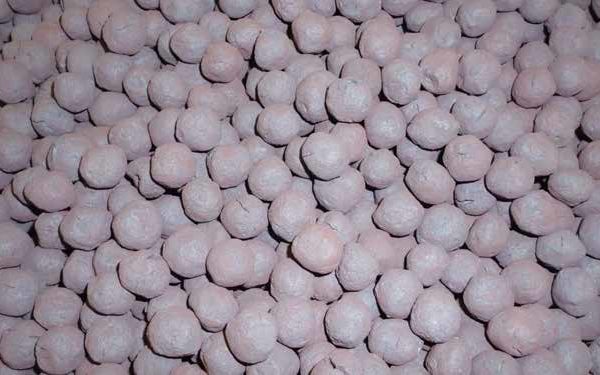

Fueling the Future of Ironmaking: MIDREX Flex™

As global efforts intensify to reduce CO2 emissions, MIDREX offers scalable solutions for transitioning towards sustainable ironmaking practices. Dive into this article from Geoff Wallwork, Midrex's Global Solutions Principal Engineer.

Most Popular

Find What You're Looking For

Filter results by the topic you’re most interested in or a particular author.